- Ultimate Handyman Forum Index TOOL FORUM Tool Talk

- Search

-

- It is currently Fri Apr 11, 2025 7:00 pm

- All times are UTC

Help - Belle 150 Mixer drive belt jumping ?

All tool questions and recommendations or complaints in this forum please

Moderator: Moderators

-

bilabonic

- Senior Member

- Posts: 426

- Joined: Sun Jul 12, 2009 10:22 am

- Location: Wales

- Has thanked: 75 times

- Been thanked: 3 times

Help - Belle 150 Mixer drive belt jumping ?

Hi

Started my belle mixer today no problem, put 5 shovels in and it started to make a racket and then tripped.

Removed cover and found belt slipping. If i put light pressure on it to apply tension it (via screwdriver...lol) works fine.

Do the belts stretch on these ? The reason i ask is that i think the motor has moved !!!!

I can see evidence of overheating on the 4 motor mounting bolts that attach to the plastic frame, the frame is slightly melted and looks as if the fixed motor has slipped/moved !!!

Anyone had this or get any thoughts on what i can do ??

Cheers

Started my belle mixer today no problem, put 5 shovels in and it started to make a racket and then tripped.

Removed cover and found belt slipping. If i put light pressure on it to apply tension it (via screwdriver...lol) works fine.

Do the belts stretch on these ? The reason i ask is that i think the motor has moved !!!!

I can see evidence of overheating on the 4 motor mounting bolts that attach to the plastic frame, the frame is slightly melted and looks as if the fixed motor has slipped/moved !!!

Anyone had this or get any thoughts on what i can do ??

Cheers

bilabonic

mikew1972

- Razor

- Senior Member

- Posts: 8760

- Joined: Wed Nov 14, 2007 10:21 pm

- Location: Northampton

- Has thanked: 483 times

- Been thanked: 1251 times

Razor

bilabonic

- thescruff

- Senior Member

- Posts: 49685

- Joined: Mon Mar 10, 2008 12:46 am

- Location: Bath

- Has thanked: 360 times

- Been thanked: 3735 times

thescruff

-

Hitch

- Senior Member

- Posts: 6055

- Joined: Mon Jan 16, 2006 8:16 pm

- Location: Somerset

- Has thanked: 77 times

- Been thanked: 335 times

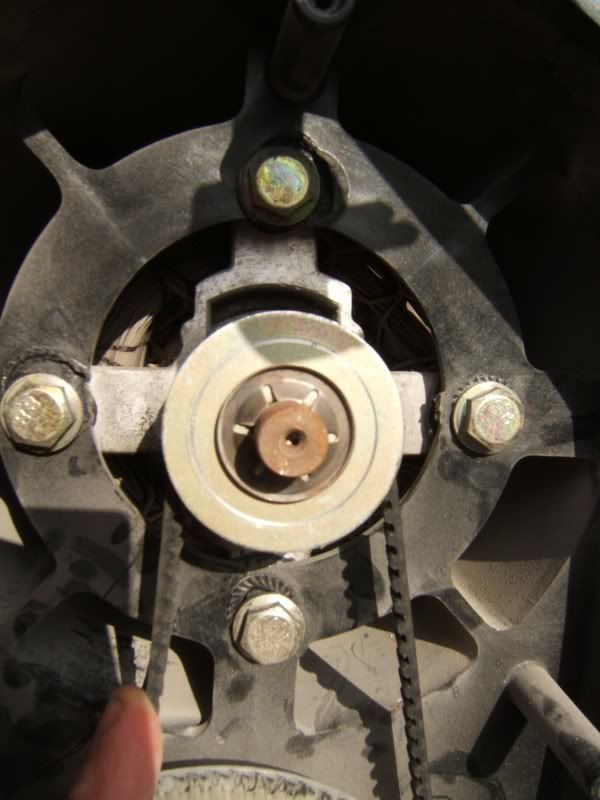

If tyhe frame the motor mouts onto has gotten warm, theres a good chance the motor position may have changed slightly- the softened plastic awllowing the drive belt to pull the motor slightly closer, rendering the belt a tiny bit too short....

Id be looking at why the plastic has melted, have you been overloading it, using it contantly for hours on end?

Could be a case of take the motor off, open out the holes slightly, and bolt it back on...

Try and post a pic of ther mountings etc

Id be looking at why the plastic has melted, have you been overloading it, using it contantly for hours on end?

Could be a case of take the motor off, open out the holes slightly, and bolt it back on...

Try and post a pic of ther mountings etc

[size=100][color=green][b]Why isn't the number 11 pronounced onety one? [/b][/color][/size]

Hitch

bilabonic

- ultimatehandyman

- Site Admin

- Posts: 24426

- Joined: Sat Jul 16, 2005 7:06 pm

- Location: Darwen, Lancashire

- Has thanked: 1012 times

- Been thanked: 918 times

Post by ultimatehandyman »

It looks like you might need a new motor housing.

When the four bolts are loosened I can't see why the motor does not move

If you could remove the bolts and move the motor, you could probably make a fixing plate to fit on the front from some plate steel.

When the four bolts are loosened I can't see why the motor does not move

If you could remove the bolts and move the motor, you could probably make a fixing plate to fit on the front from some plate steel.

ultimatehandyman

Hitch

- thescruff

- Senior Member

- Posts: 49685

- Joined: Mon Mar 10, 2008 12:46 am

- Location: Bath

- Has thanked: 360 times

- Been thanked: 3735 times

thescruff

-

bilabonic

- Senior Member

- Posts: 426

- Joined: Sun Jul 12, 2009 10:22 am

- Location: Wales

- Has thanked: 75 times

- Been thanked: 3 times

I you saying this from experience/knowledge or just from viewing the pics.thescruff wrote:The motor goes up on the left, the right hole/bolt is fixed, so lever from the side not the bottom.

As i said i have removed all bolts and in no way are the fixing holes elongated in any way for motor adjustment.

Also what can not be seen is the main motor supports which run the entire length, these are also melted and the motor has dropped and stuck fast as far as i can see.

Have you adjusted one before ???

bilabonic

- thescruff

- Senior Member

- Posts: 49685

- Joined: Mon Mar 10, 2008 12:46 am

- Location: Bath

- Has thanked: 360 times

- Been thanked: 3735 times

thescruff

bilabonic

mikew1972

-

bilabonic

- Senior Member

- Posts: 426

- Joined: Sun Jul 12, 2009 10:22 am

- Location: Wales

- Has thanked: 75 times

- Been thanked: 3 times

Cheers mate. I'm a Sparky so no doubt i can butcher something up. It is not as simple as just elongating the holes as the motor still will not move.mikew1972 wrote:OK then, make some - elongate the holes a bit then push the motor up to the top of the slots you made. How deep into wales are you? I'm in cheshire and can do it for you for a bit of beer money if you can't?

The whole length is is stuck fast/melted. I may just make a tensioner for the belt.

Cheers for help guys, much appreciated. Will let you know how i get on.

bilabonic

Jump to

- Ultimate Handyman DIY forum

- ↳ Welcome to the Ultimate Handyman DIY Forum

- WELCOME

- ↳ WELCOME

- ↳ About the forums

- UltimateHandyman Discounts

- ↳ Ultimatehandyman Discounts

- ULTIMATE HANDYMAN COMPETITIONS

- ↳ UHM Forum competitions

- SHOW CASE- A place to show us your work

- ↳ Show Case Gallery

- ↳ Rogues Gallery

- TOOL FORUM

- ↳ Power Tool Reviews

- ↳ Bosch

- ↳ budget power tools

- ↳ Dewalt

- ↳ Festool

- ↳ Hikoki/Hitachi

- ↳ Makita

- ↳ Metabo

- ↳ Milwaukee

- ↳ Ryobi

- ↳ Tool Talk

- ↳ Bargain Tools

- ↳ Hand tool reviews

- ↳ Power Tool Manuals

- ↳ Bosch

- ↳ Dolmar

- ↳ ELEKTRA BECKUM

- ↳ Hitachi

- ↳ Husqvarna

- ↳ Jonsered

- ↳ Makita

- ↳ Stihl

- Other DIY

- ↳ Computers

- ↳ communications and broadband

- ↳ Gardeners World

- ↳ Money Saving

- ↳ Vehicle maintenance & Repair

- ↳ Energy Saving

- DIY Forum/Home improvement

- ↳ General DIY forum

- ↳ Acrylic Forum

- ↳ DIY Disasters

- ↳ Stoves

- ↳ Building Forum

- ↳ Carpentry/Joinery Forum

- ↳ Kitchen Fitting

- ↳ Damp Proofing and Remedial problems

- ↳ Electric Forum UK

- ↳ Lighting

- ↳ Alarm Manuals

- ↳ Painting & Decorating Forum

- ↳ Plastering Forum

- ↳ Plumbing Forum

- ↳ Central Heating & Boilers

- ↳ Boiler Manuals

- ↳ Alpha

- ↳ Ariston

- ↳ ATAG

- ↳ Atmos

- ↳ Baxi

- ↳ Biasi

- ↳ Broag

- ↳ Chaffoteux

- ↳ Ferroli

- ↳ Glow-worm

- ↳ Halstead

- ↳ Ideal

- ↳ Intergas

- ↳ Keston

- ↳ Myson

- ↳ Potterton

- ↳ Protherm

- ↳ Ravenheat

- ↳ Saunier Duval

- ↳ Sime

- ↳ Thorn

- ↳ Vaillant

- ↳ Viessmann

- ↳ Vokera

- ↳ warmflow

- ↳ Worcester Bosch

- ↳ Shower Manuals

- ↳ Tiling Forum

- ↳ Metalworking Forum

- General

- ↳ The Lounge

- ↳ The games corner

- ↳ The Grumpy corner

- ↳ The Sport corner

- ↳ The Cookery corner

- ↳ The Music Corner

- ↳ BUY - SELL - FREE