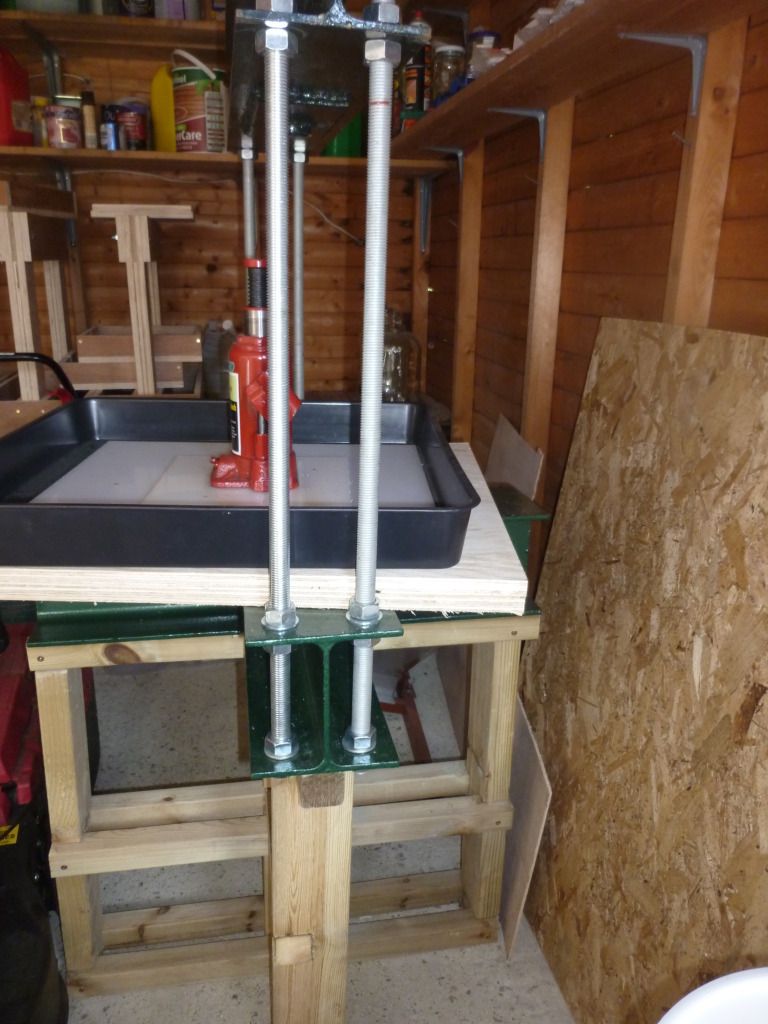

I have recently built a cider press (pictured and videoed below). It has had one year of operation and was successful however whatever we put between the jack and the apples snapped/broke/bent (Including Oak, Break disks, plastic and a combination of the aforementioned). Which is not great. This year we used a 10 ton jack, I do want to upgrade to 20 tons next year though and I need something to go between the jack and the apples!

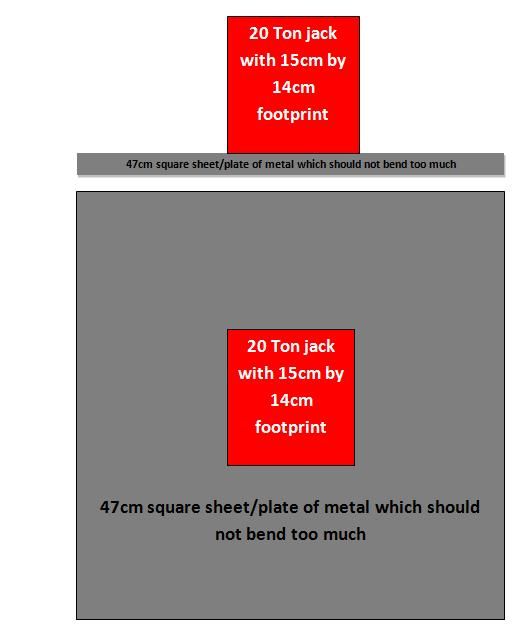

The base of the jack the new jack would be a bit bigger around 14cm by 15cm (that is the smallest it would be). The plate of metal would need to be 47cm by 47cm and have the jack on top of it and not bend too much.

I have no idea about which metal to use - which is strongest for the type of use I am using it for and how thick it should be or even where to get it from - this is where I thought you guys might be able to help? I am based in West Sussex.

Thanks for any help!